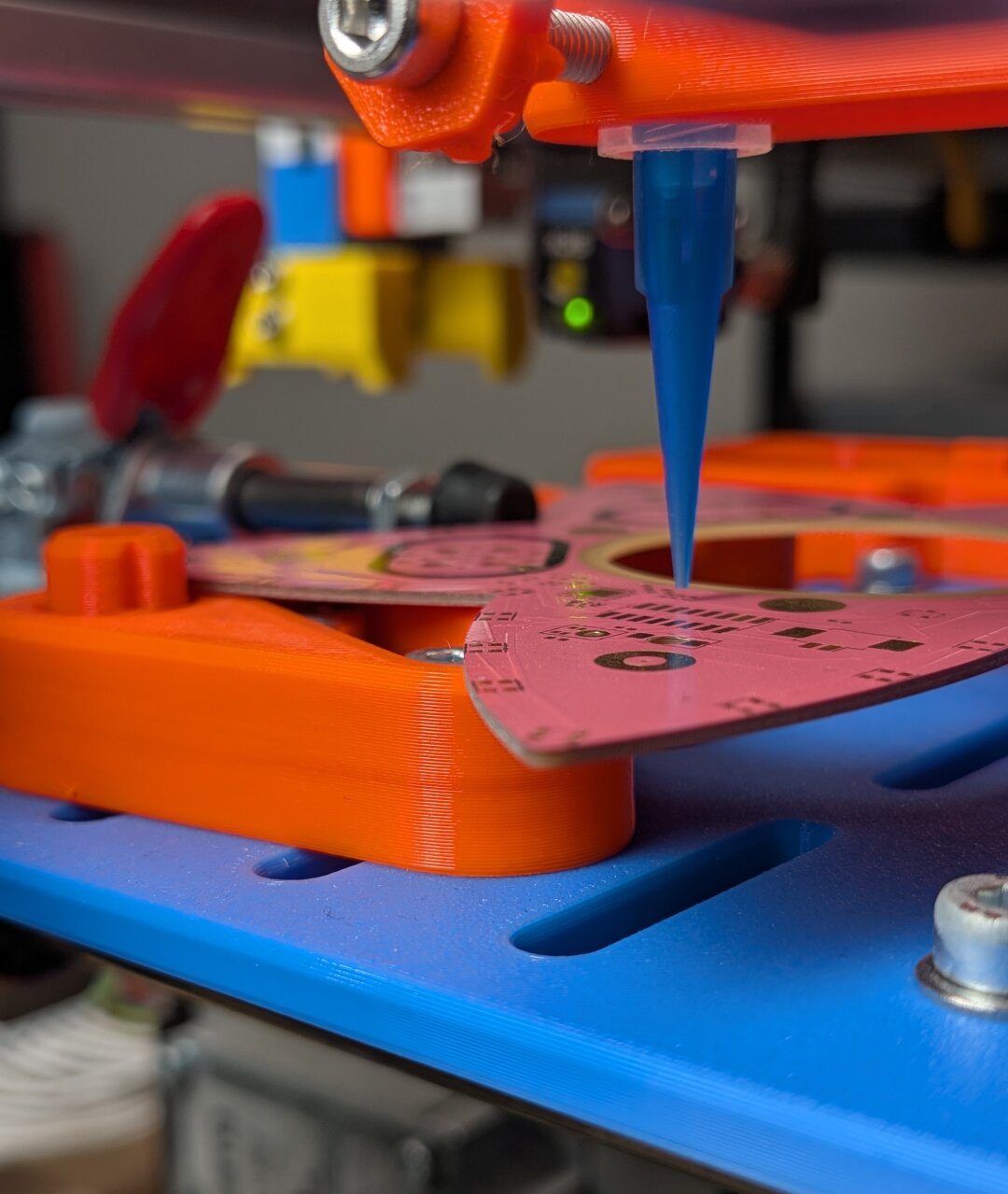

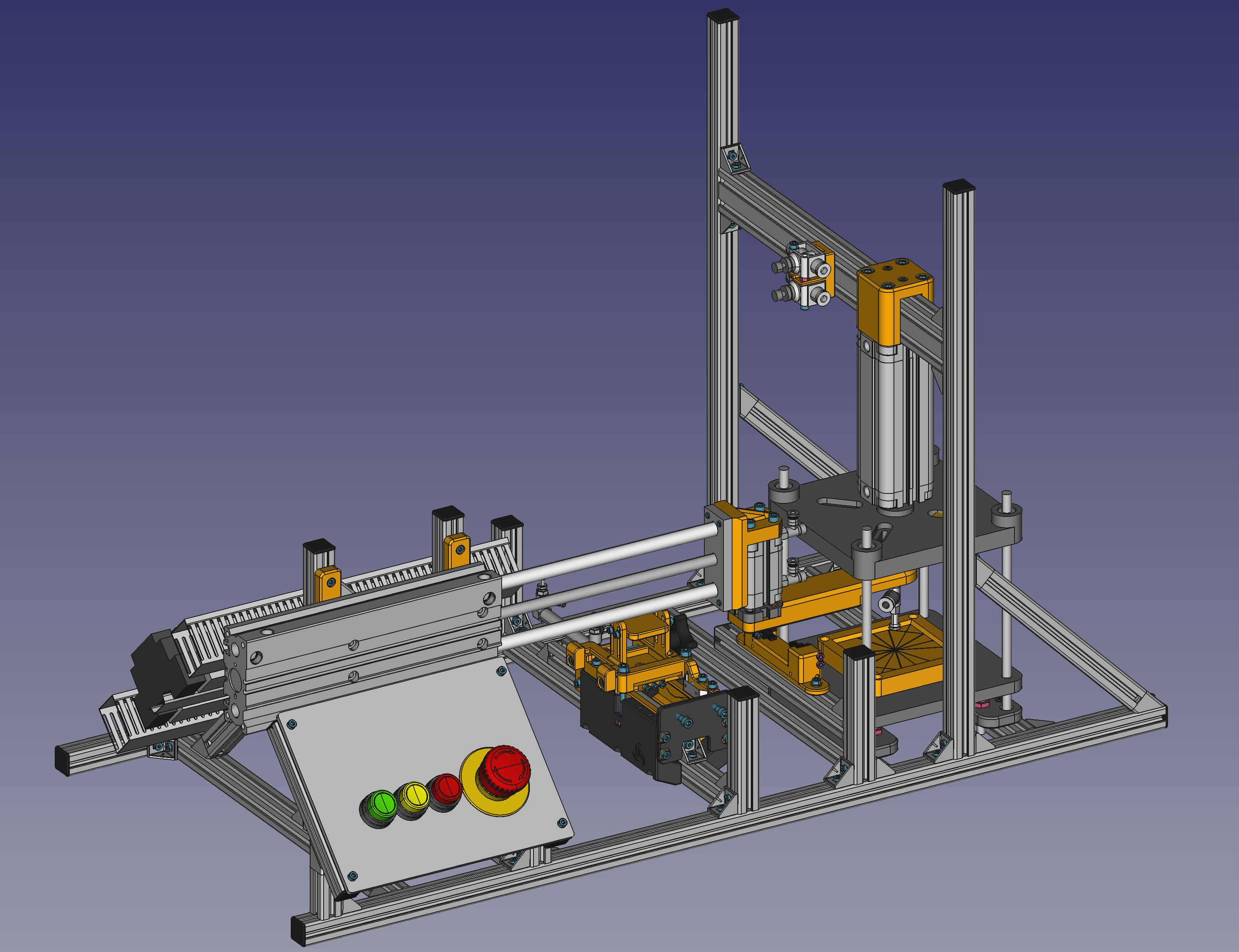

In 2023, I built a machine called the "CNC Adhesive Applicator", to automate the process of attaching a display to a custom PCB using adhesives. In typical fashion, I only get to writing about it now. But better late than never! So here is a blog post about all the details.

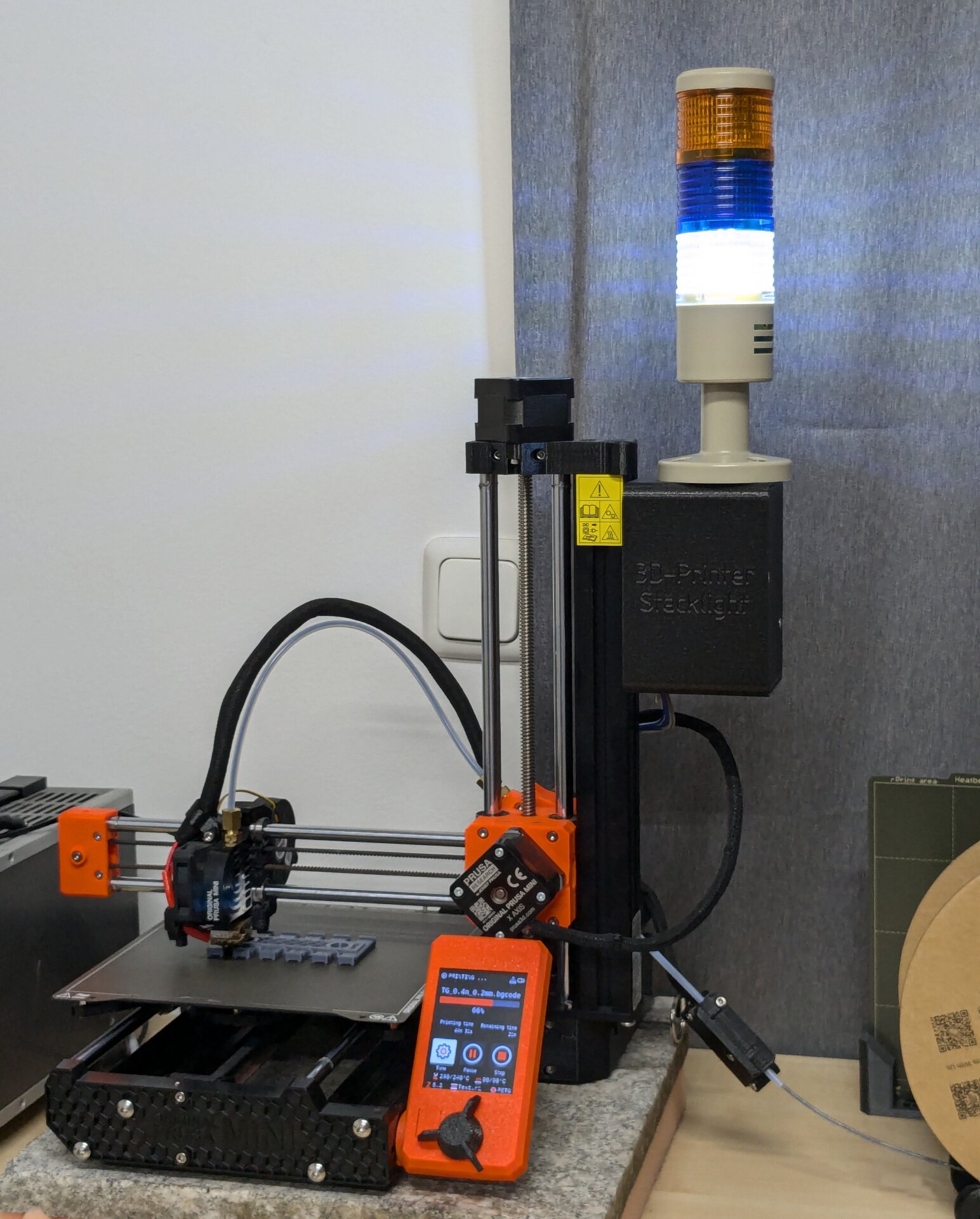

Many industrial machines signal their status using stack lights. They are simple technology and make it super easy to see machine status at a glance. Especially on a production floor full of machines, stack lights allow quickly gauging where attention is needed.

So naturally, I wanted to augment my 3d-printer with such a stack light, to see what it is up to, without walking over. And I want to show you how you can do it too, while also sharing some stack light lore.

I want to announce the release of a project that I have been working on in the past months: profirust is a PROFIBUS-DP compatible communication stack written in Rust!

On my quest to dive deeper and deeper into the industrial automation world, it was inevitable for me to explore the various fieldbus protocols at some point. Especially for supporting my increasingly complex machinery, I wanted to look into a robust and scalable fieldbus solution. PROFIBUS uses purple cabling so naturally I felt like this was the option I had to choose.

As there are few to no existing open-source projects implementing a fully capable PROFIBUS communication stack, this looked like a promising niche to fill and an interesting challenge to attempt solving.

Accompanying the release of profirust, a PROFIBUS-DP compatible communication stack, I want to provide an introduction to PROFIBUS in general.

While PROFIBUS is quite dated at this point, there are still massive amounts of PROFIBUS installations in service around the world. It's also quite interesting to dig into this bus protocol from a historical perspective — to understand where modern industrial protocols originate from.

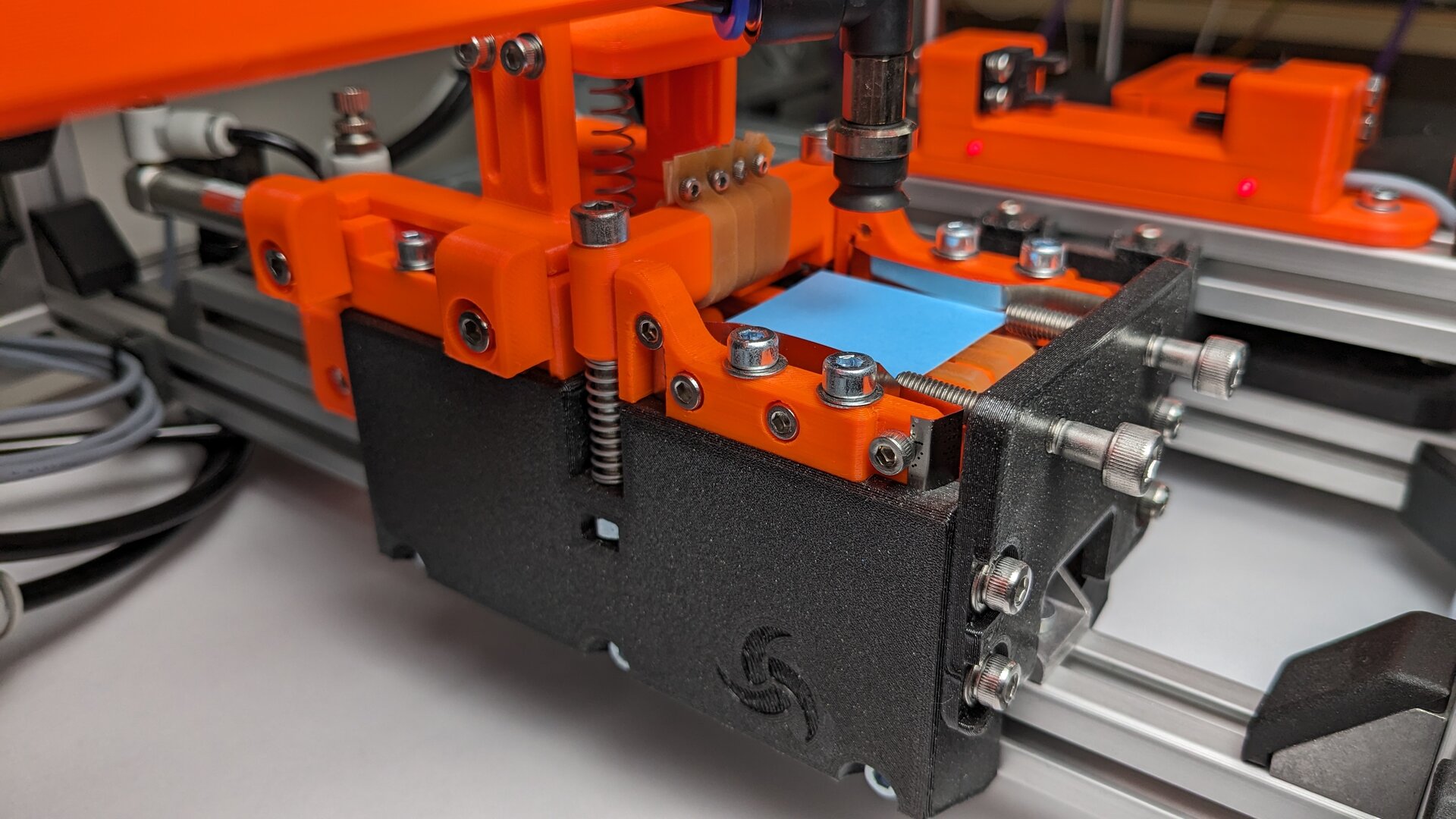

This is the next article in the series about our "Flower Machine".

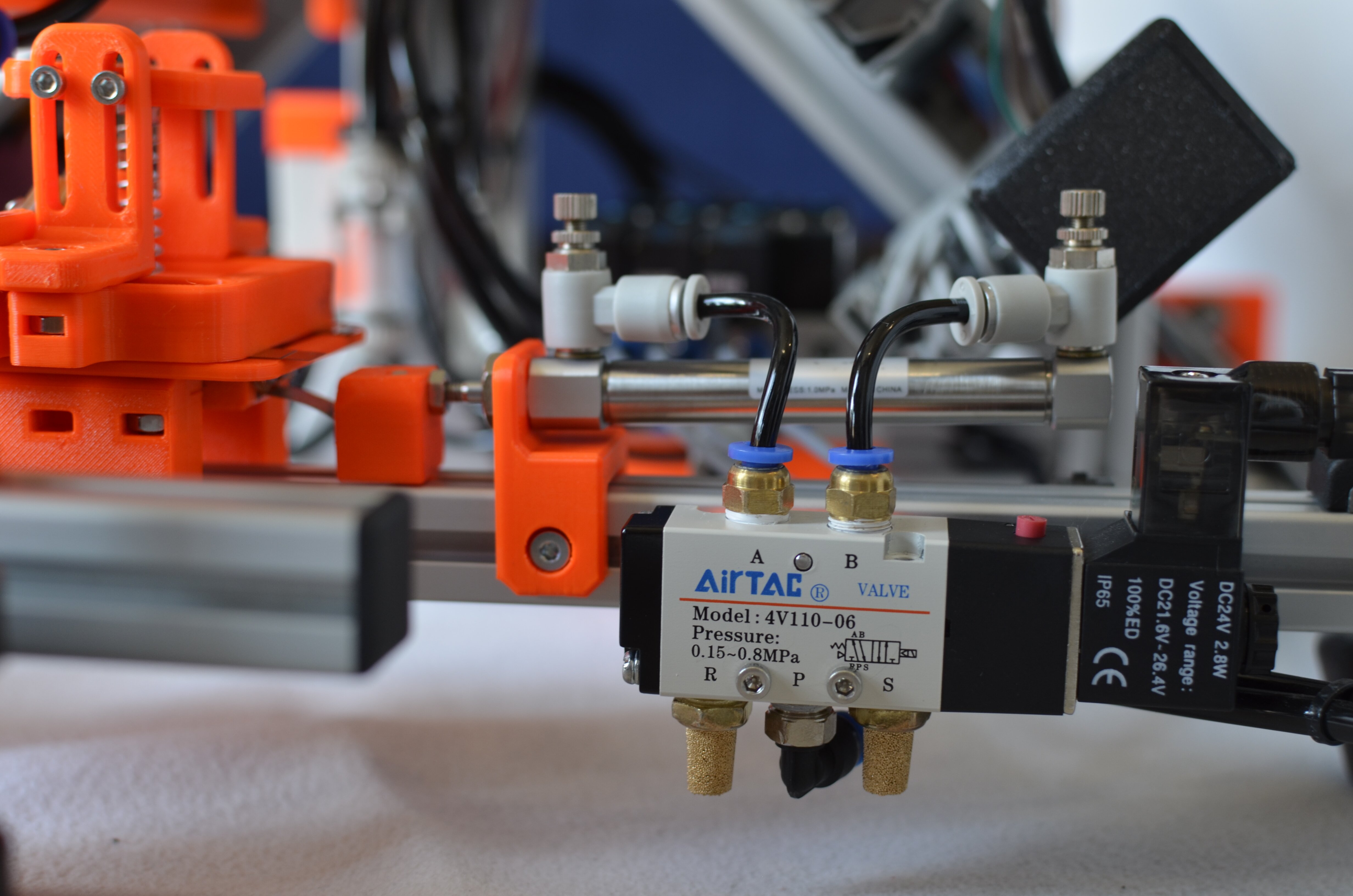

For a fully automatic process, the "raw materials" must also be fed into the machine completely automatically. For the Flower Machine, this means feeding small paper squares one at a time. The obvious storage format is a stack of paper - but how do you pick a single piece of paper from a stack?

Feeding paper reliably was probably the hardest challenge in the Flower Machine project. In this post, I will present all the details it took to get the paper-feeding mechanism working.

This is the next article in the series about our "Flower Machine".

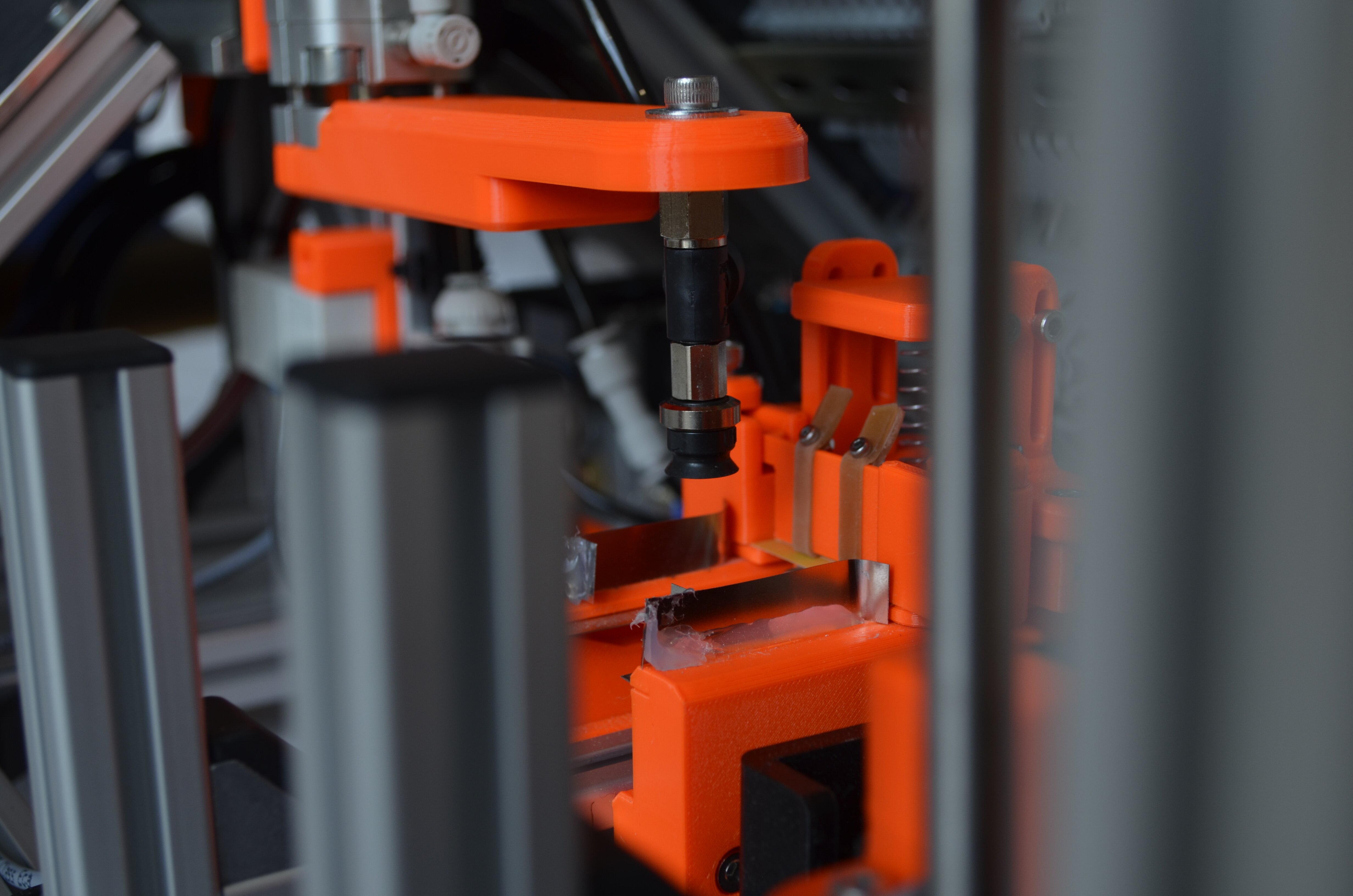

Just a quick one: Let's talk about some of the mechanical design elements in the Flower Machine project.

This is the next article in the series about our "Flower Machine".

Back in the first post about the flower machine, we talked about what it is doing. It is time to introduce how it actually works. There are already some posts about very specific topics like pneumatics or the logic controller. Before writing more posts like these, I think it is a good idea to look at the bigger picture.

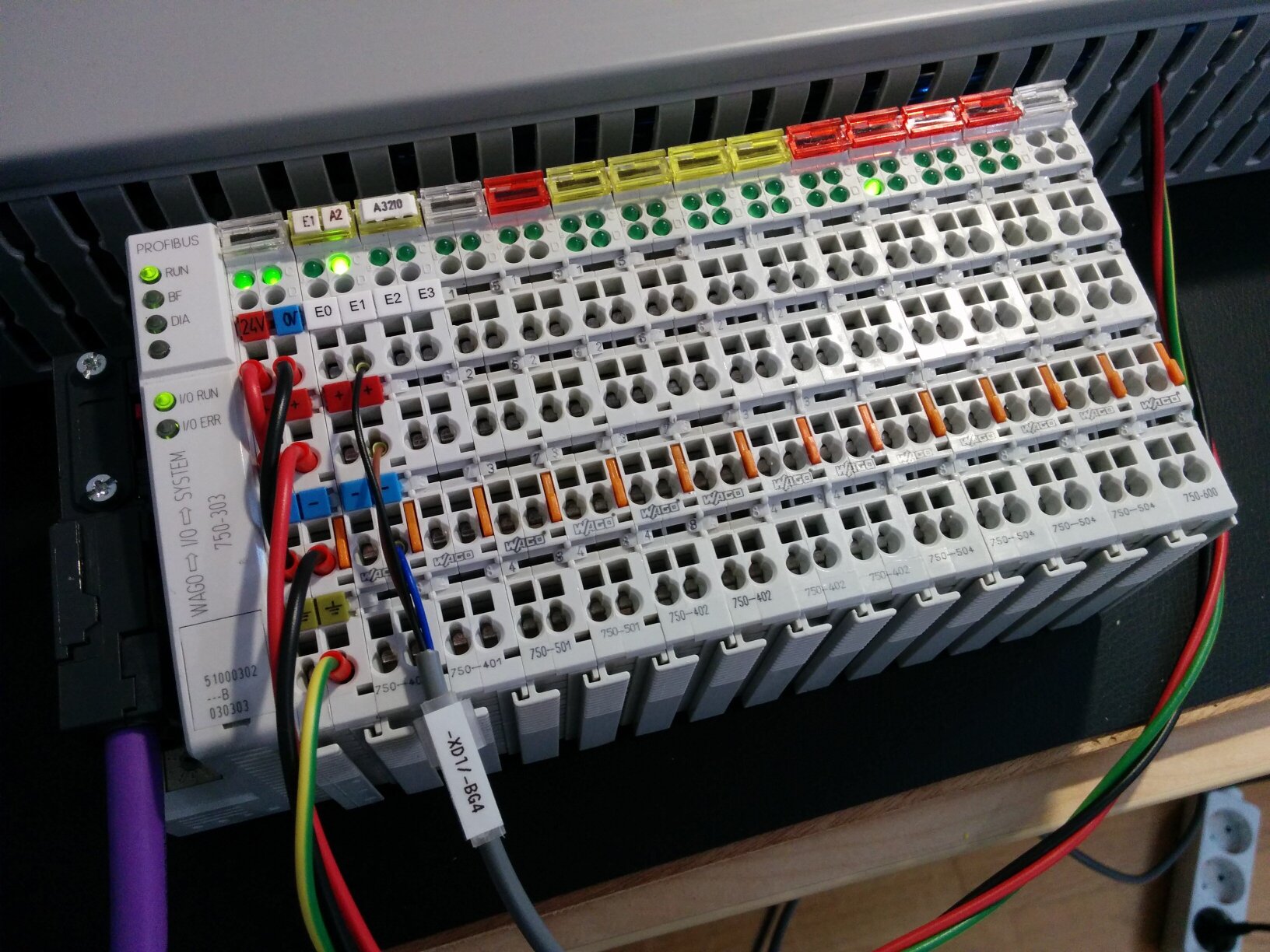

Something not (quite) Flower Machine related for once. I got myself a WAGO 750 remote I/O station with a 750-303 PROFIBUS coupler. This post is documentation how I got it working with the open-source PROFIBUS-DP stack pyprofibus.

This is the next article in the series about our "Flower Machine".

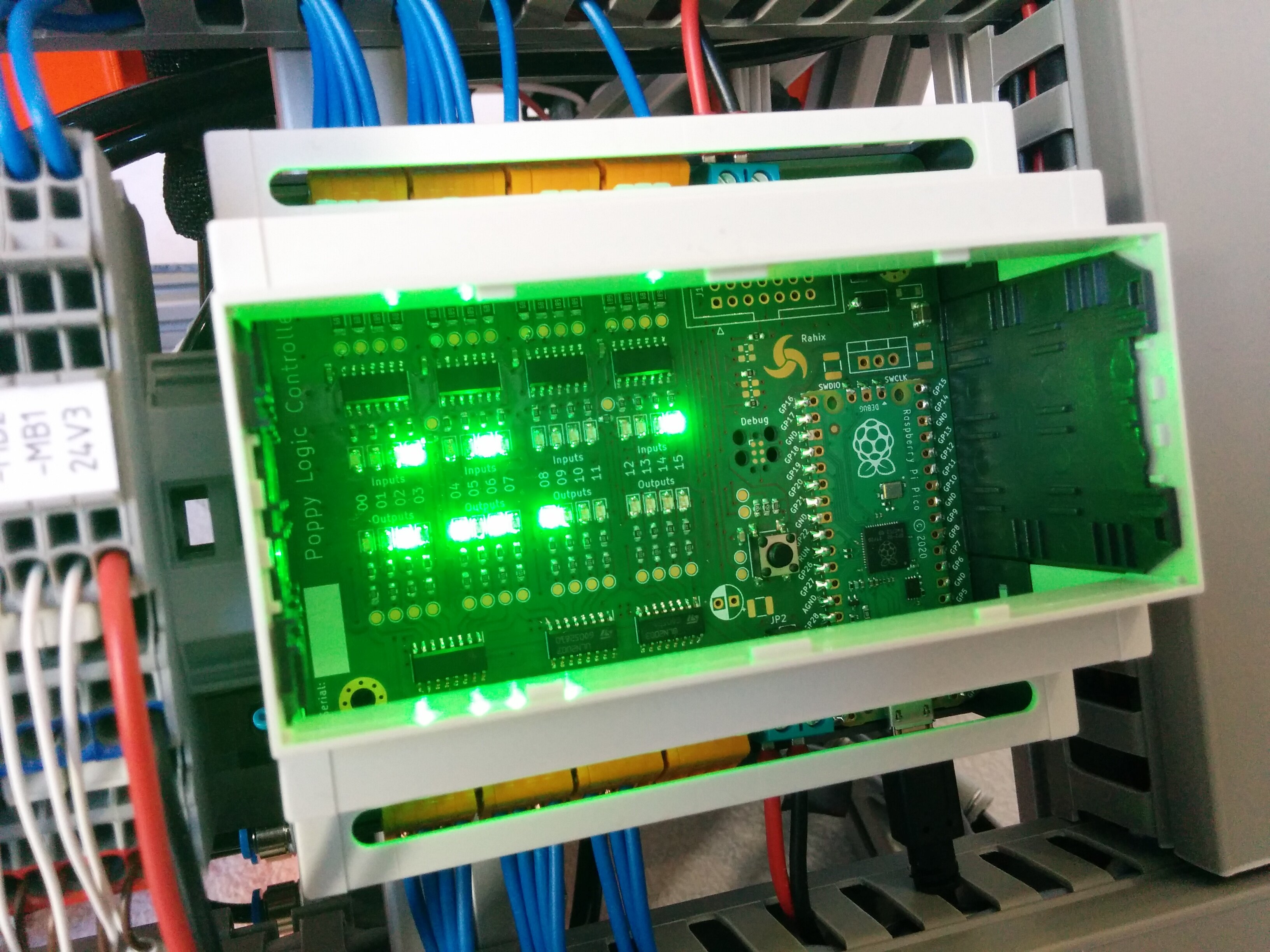

Of course a machine like this would be useless without any brain to control it. The industrial solution is called a PLC (Programmable Logic Controller). However a real PLC has a number of deal-breakers for us: It is expensive, full of proprietary software, and 99% of the time programming it is windows-only.

Thus I set out to build an alternative: Meet the Poppy Logic Controller - a custom PLC-like device which mimics the real thing, but on a budget.

In this post, I will go over the hardware side. A future post about the software/firmware will follow. You can also find all hardware design files and firmware sources on GitHub: https://github.com/Rahix/Poppy-Logic-Controller

This is the next article in the series about our "Flower Machine".

Pneumatics means using compressed air to perform mechanical work. Our Flower Machine actually works using pneumatics only! But why would you choose pneumatics? And what components are needed? In this blog post, we will give an overview of pneumatics and their relationship with automating manufacturing.

Hey, I am back! Well, we are back. That's because this post is written not only by me but also by my lovely girlfriend Lena.

We've been busy with a shared project over the last months. It started back in December when we both really wanted to dive into the topic of pneumatics. We searched for a small project we could build. Well, in the end we didn't manage to keep it small. In this and following blog posts, we will present where this lead us...