Hey, I am back! Well, we are back. That's because this post is written not only by me but also by my lovely girlfriend Lena.

We've been busy with a shared project over the last months. It started back in December when we both really wanted to dive into the topic of pneumatics. We searched for a small project we could build. Well, in the end we didn't manage to keep it small. In this and following blog posts, we will present where this lead us...

Playing with Pneumatics

So what could we possibly do with pneumatics? The first idea was a robot arm of sorts. But the first thing we learned is that pneumatics is very bad for arbitrary positioning. We will get back to that in a later post. So something else was needed. We quickly found out that pneumatics is heavily used in the automation industry. There's so much to discover there that it quickly got us hooked. Let's build a machine that automates a manufacturing process!

Now the problem was: What process? It can't be too difficult - we're just getting started - but it should also not be boring. We didn't want to build yet another sorting conveyer belt or pneumatic can crusher. Those are nice and all but we wanted something more novel and exciting.

Paper Flowers

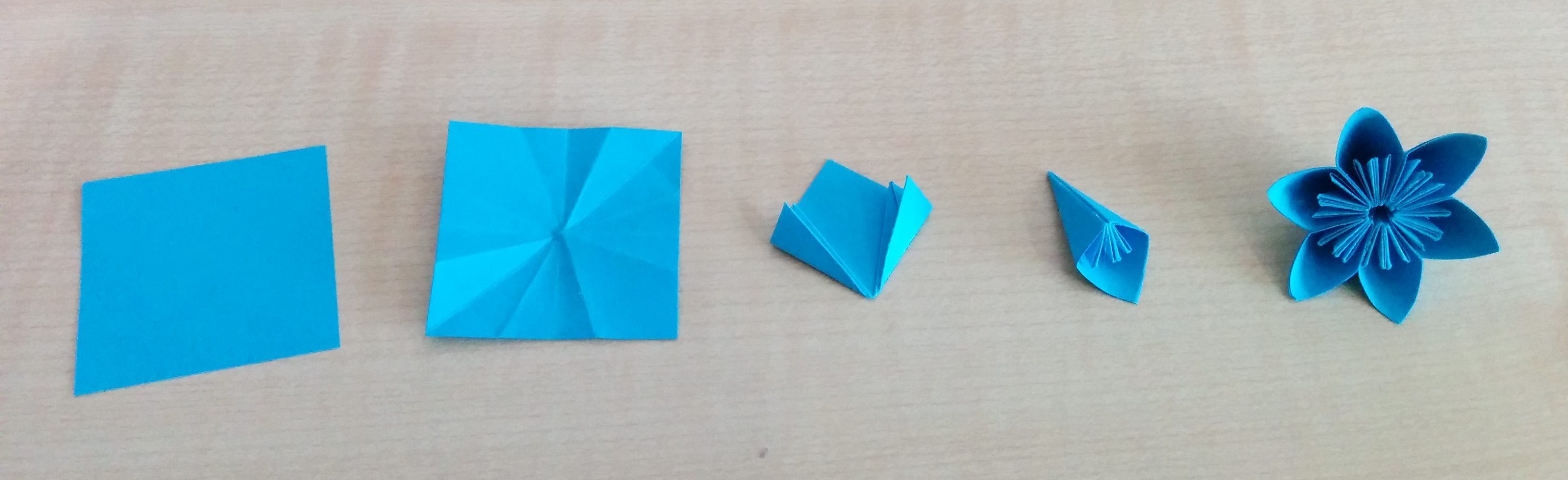

So we looked elsewhere. Those who know me (rahix) personally have probably at some point noticed my weird obsession with folding paper flowers. Not origami - often there is glue and cutting involved with these flowers - but something close to it. Some people have coined the term "fleurogami" for it. I can't tell why, but I'm absolutely addicted. Don't leave me alone with paper, it does not end well. Here are a few pictures:

A lot of these flowers consist of the same basic module repeated over and over again. That sounds great for mass production! A process we can automate? The only problem is: Folding paper precisely is hard... Building a machine that does it will be even harder :(

But even in the industry, not everything is done by machines. The tricky bits are often still left to the humans. Just all the "easy" parts in between are automated. We chose to do the same thing: Take one of the steps in the process that is easy to automate and build a machine for it. The harder steps are left for the factory workers (= rahix).

Flower Folding

The first thing you need to do before starting an automation project is understanding the process extremely well. Your automation will only be as good as your understanding of the process. So let's look at it in detail. Here is how a paper square gets folded into a flower:

- The pattern of mountain and valley folds is creased into the paper. The folds usually have some geometric relationships that you can use to build up the pattern. Precision is key here - it will greatly influence the final look.

- The pattern is then collapsed by "applying" all of those folds. This is the hard-to-automate part because everything has to be done in the right order and the paper does not stay flat while doing it.

- In this case, the module is then glued in one spot to complete it.

- And finally 6 modules are glued together to create a flower.

When folding by hand, steps 1 and 2 often fuse into one. But separating them reveals an opportunity: Creasing a pattern into paper is something we can easily automate! We need a top and bottom die which each have blades to crease the paper. Then sandwich a paper in between and press it all together.

This then yields a precise pattern in the paper and step 2 gets sped up quite a bit because it is now only about collapsing the premade folds. Still hard for a machine, but quick and easy for a human.

Flower Machine

Well then, the goal was to build a machine which automatically creases patterns into paper. It took a while, we learned a lot, but in the end, we made this project a reality. Here it is, our "Flower Machine":

In the following posts, we will go into all the details of what it took to get here. Many disciplines were involved, from mechanical engineering to electronics to programming. That's what made it so interesting for us. Stay tuned for more. In the meantime, here is the machine in action :)

If you want, you can read the next blog-post in the Flower Machine series here: Flower Machine: Technical Overview. Or head to the overview of all flower-machine posts.