Hey, I am back! Well, we are back. That's because this post is written not only by me but also by my lovely girlfriend Lena.

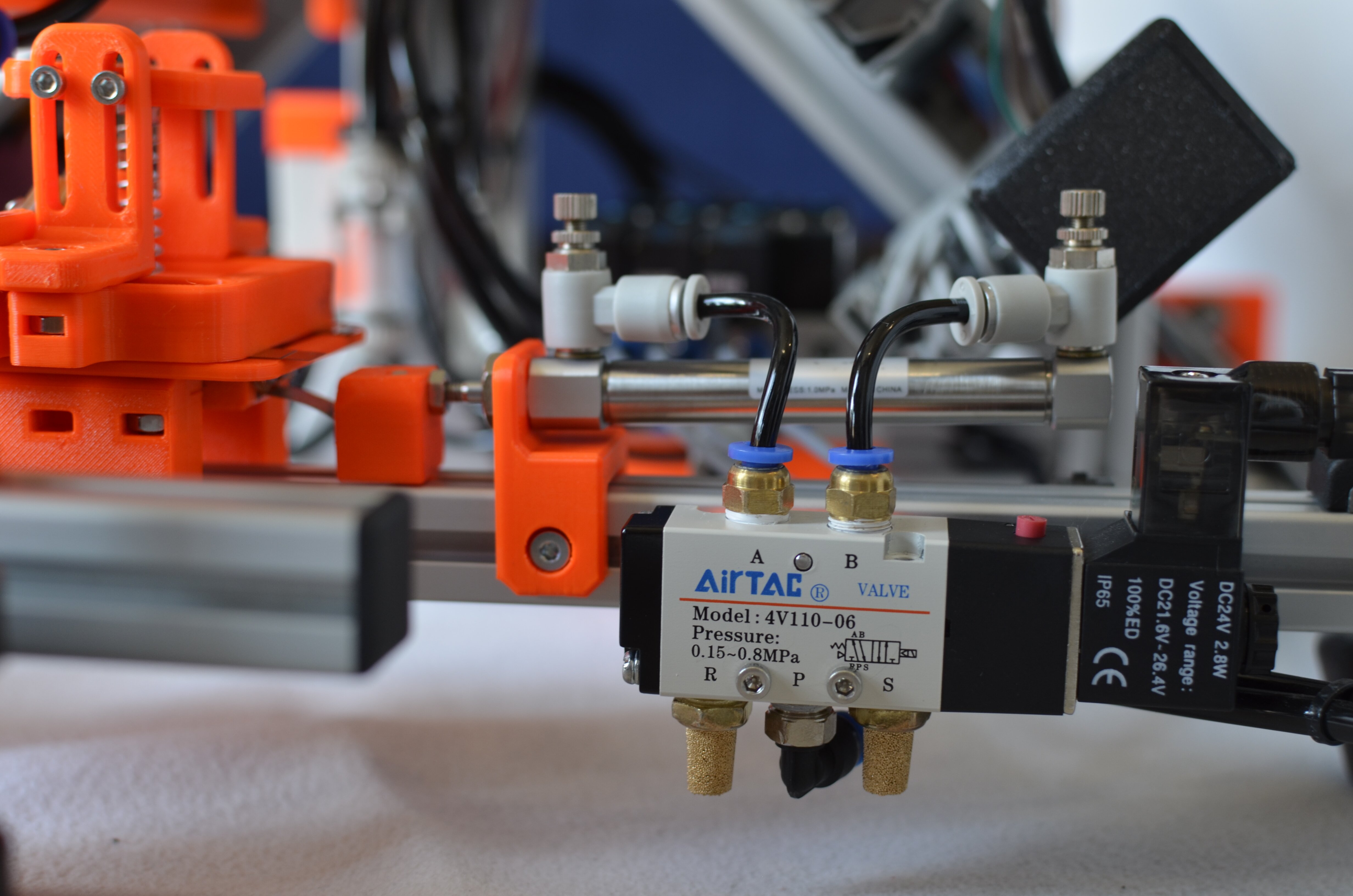

We've been busy with a shared project over the last months. It started back in December when we both really wanted to dive into the topic of pneumatics. We searched for a small project we could build. Well, in the end we didn't manage to keep it small. In this and following blog posts, we will present where this lead us...

This is the next article in the series about our "Flower Machine".

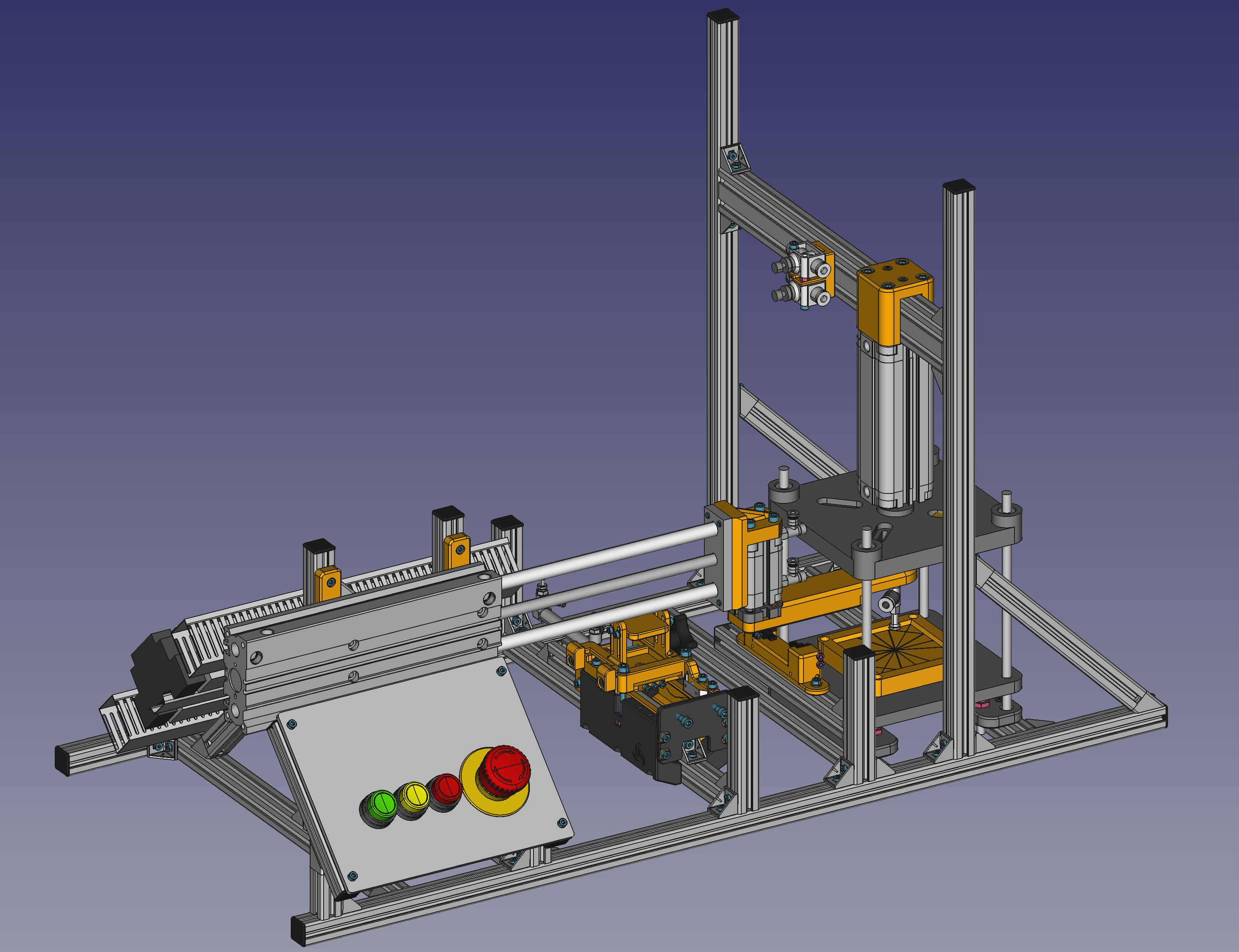

Back in the first post about the flower machine, we talked about what it is doing. It is time to introduce how it actually works. There are already some posts about very specific topics like pneumatics or the logic controller. Before writing more posts like these, I think it is a good idea to look at the bigger picture.

This is the next article in the series about our "Flower Machine".

Pneumatics means using compressed air to perform mechanical work. Our Flower Machine actually works using pneumatics only! But why would you choose pneumatics? And what components are needed? In this blog post, we will give an overview of pneumatics and their relationship with automating manufacturing.

This is the next article in the series about our "Flower Machine".

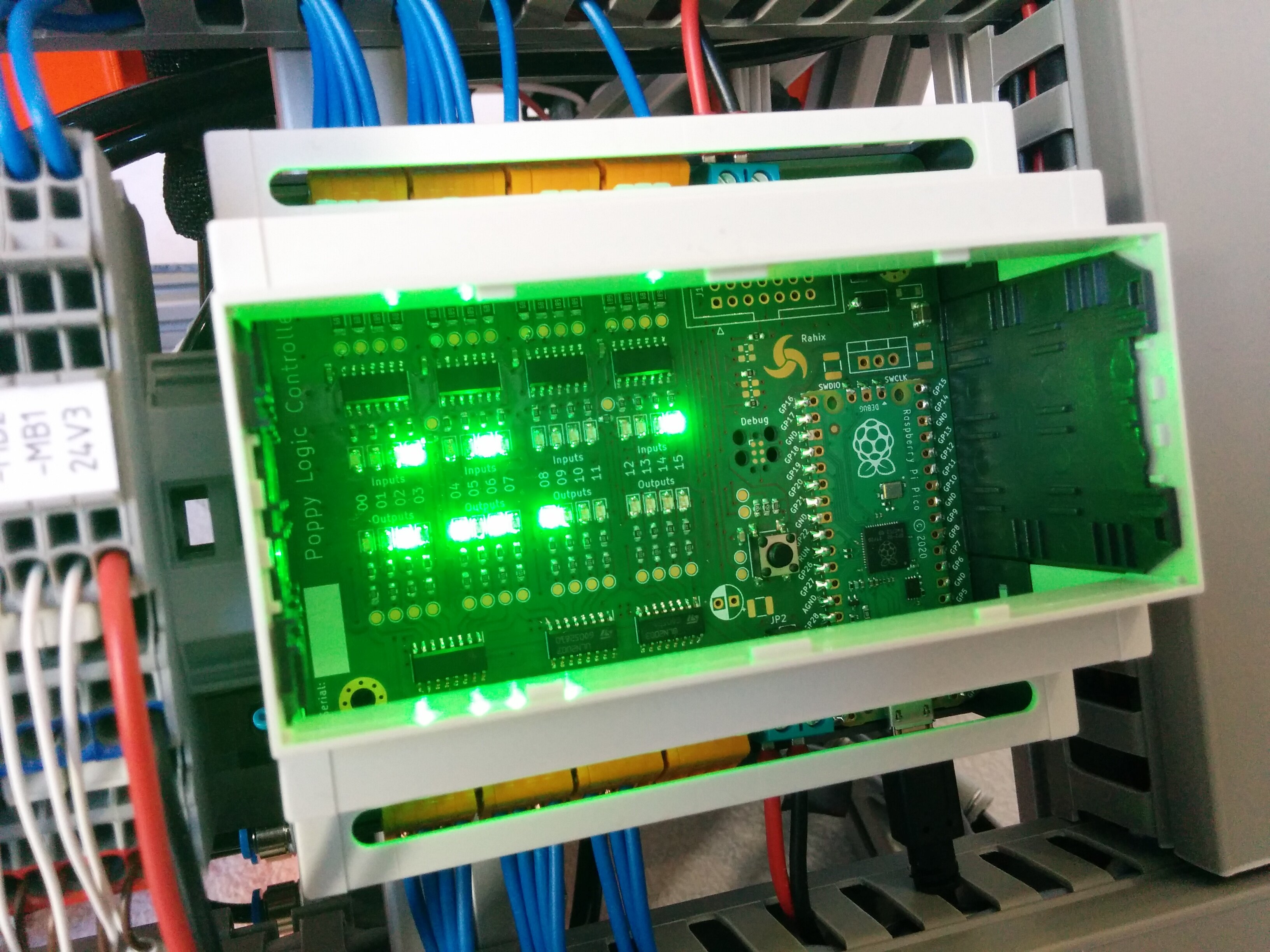

Of course a machine like this would be useless without any brain to control it. The industrial solution is called a PLC (Programmable Logic Controller). However a real PLC has a number of deal-breakers for us: It is expensive, full of proprietary software, and 99% of the time programming it is windows-only.

Thus I set out to build an alternative: Meet the Poppy Logic Controller - a custom PLC-like device which mimics the real thing, but on a budget.

In this post, I will go over the hardware side. A future post about the software/firmware will follow. You can also find all hardware design files and firmware sources on GitHub: https://github.com/Rahix/Poppy-Logic-Controller

This is the next article in the series about our "Flower Machine".

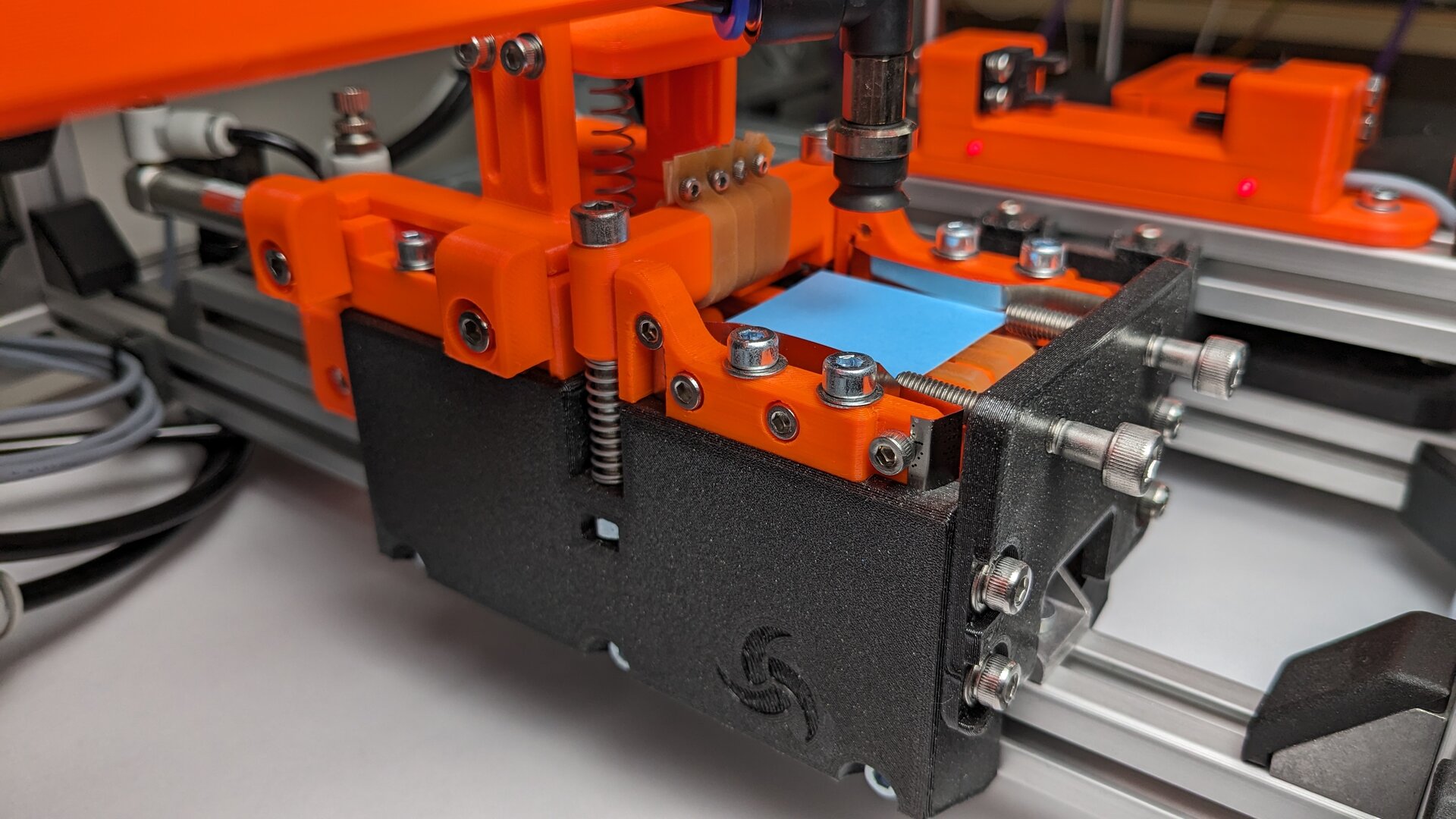

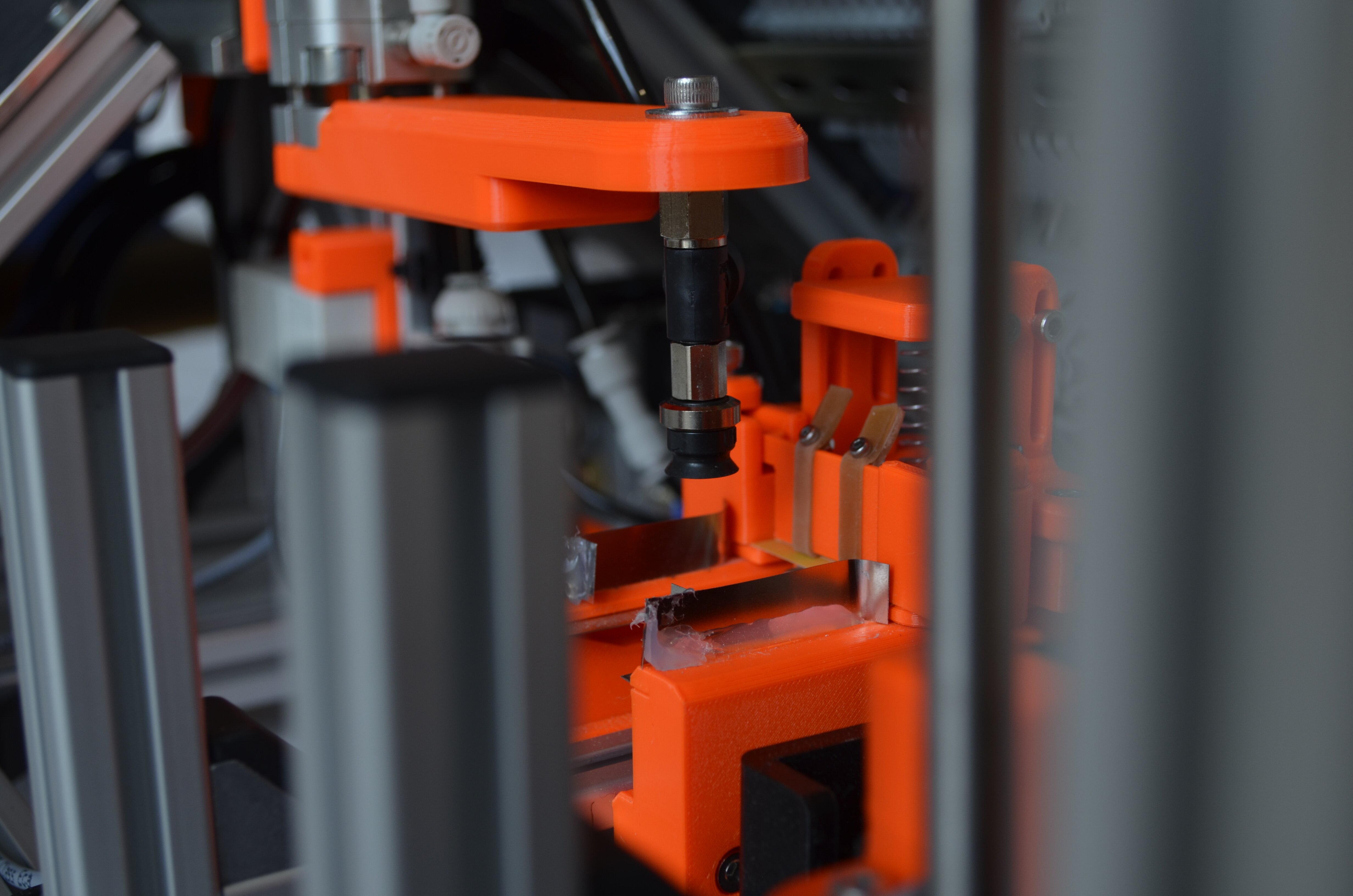

Just a quick one: Let's talk about some of the mechanical design elements in the Flower Machine project.

This is the next article in the series about our "Flower Machine".

For a fully automatic process, the "raw materials" must also be fed into the machine completely automatically. For the Flower Machine, this means feeding small paper squares one at a time. The obvious storage format is a stack of paper - but how do you pick a single piece of paper from a stack?

Feeding paper reliably was probably the hardest challenge in the Flower Machine project. In this post, I will present all the details it took to get the paper-feeding mechanism working.