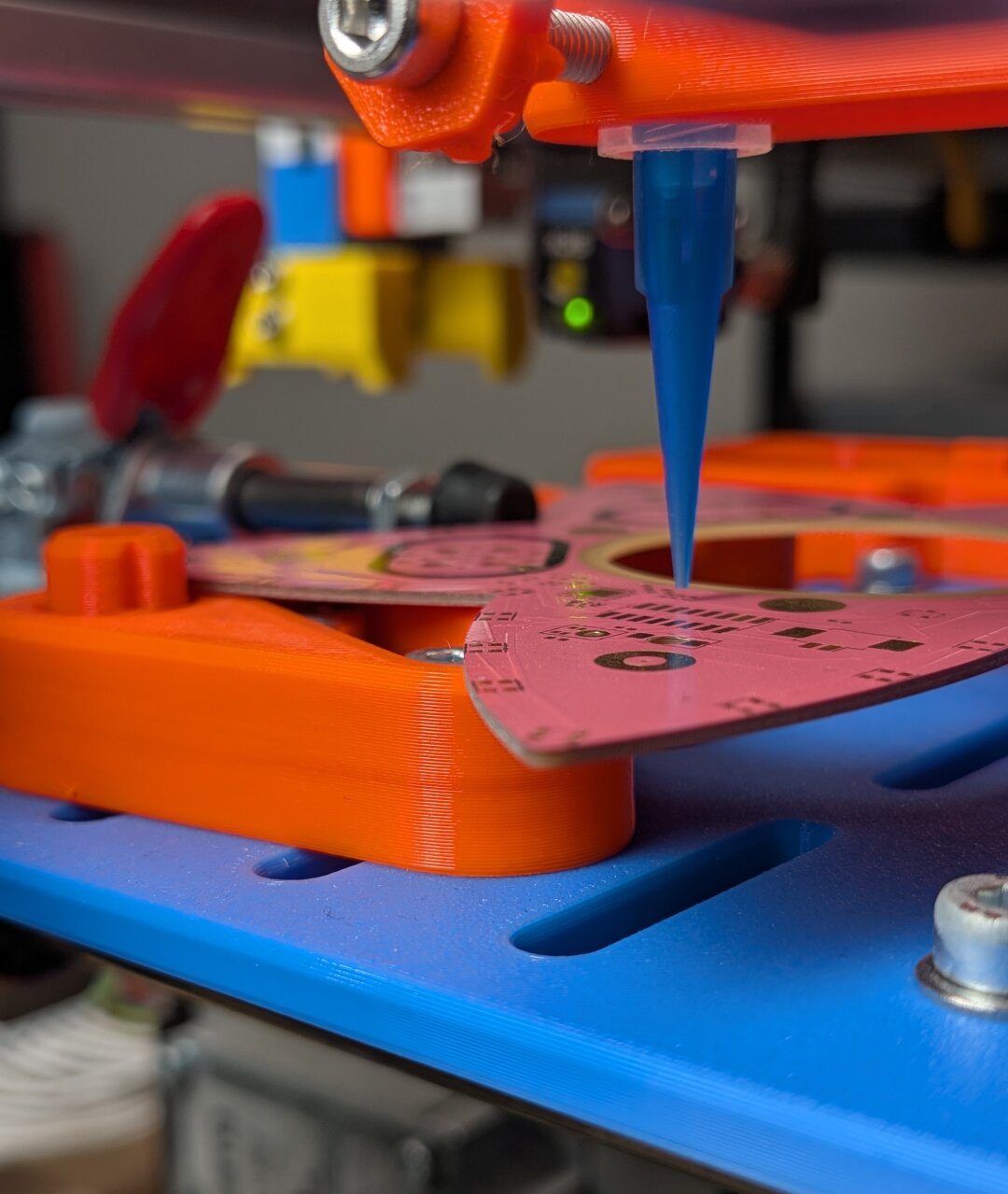

In 2023, I built a machine called the "CNC Adhesive Applicator", to automate the process of attaching a display to a custom PCB using adhesives. In typical fashion, I only get to writing about it now. But better late than never! So here is a blog post about all the details.

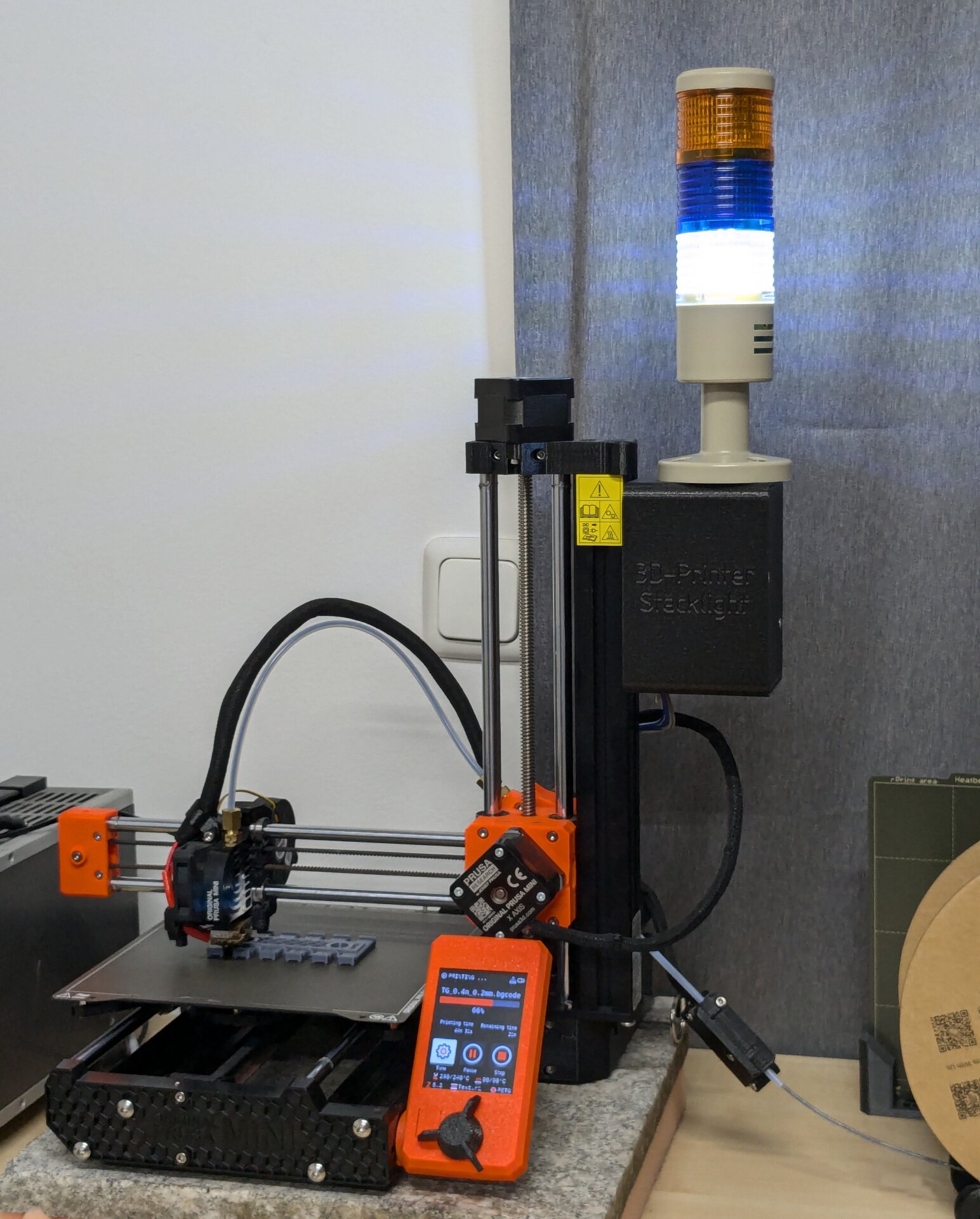

Many industrial machines signal their status using stack lights. They are simple technology and make it super easy to see machine status at a glance. Especially on a production floor full of machines, stack lights allow quickly gauging where attention is needed.

So naturally, I wanted to augment my 3d-printer with such a stack light, to see what it is up to, without walking over. And I want to show you how you can do it too, while also sharing some stack light lore.

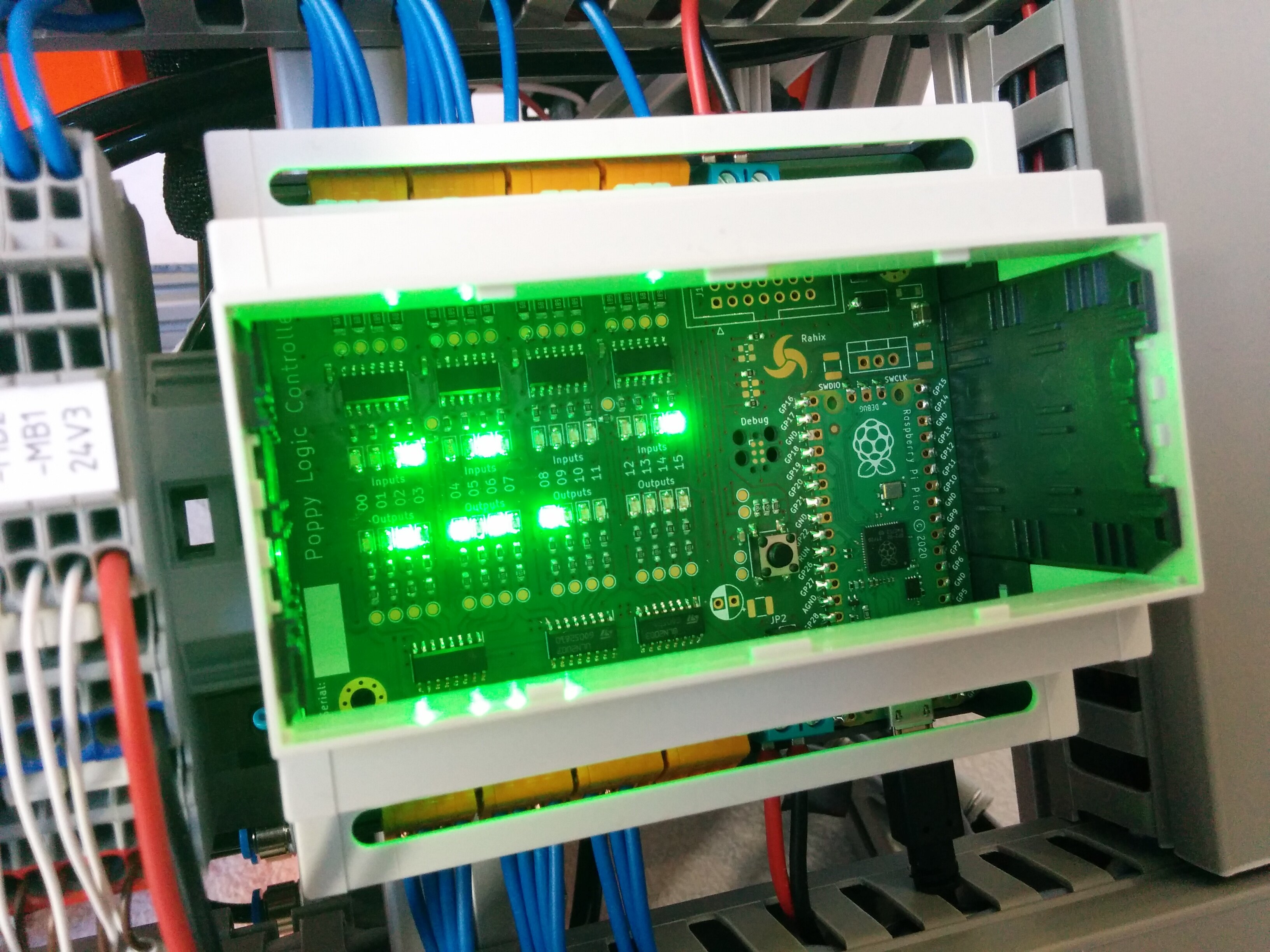

This is the next article in the series about our "Flower Machine".

Of course a machine like this would be useless without any brain to control it. The industrial solution is called a PLC (Programmable Logic Controller). However a real PLC has a number of deal-breakers for us: It is expensive, full of proprietary software, and 99% of the time programming it is windows-only.

Thus I set out to build an alternative: Meet the Poppy Logic Controller - a custom PLC-like device which mimics the real thing, but on a budget.

In this post, I will go over the hardware side. A future post about the software/firmware will follow. You can also find all hardware design files and firmware sources on GitHub: https://github.com/Rahix/Poppy-Logic-Controller

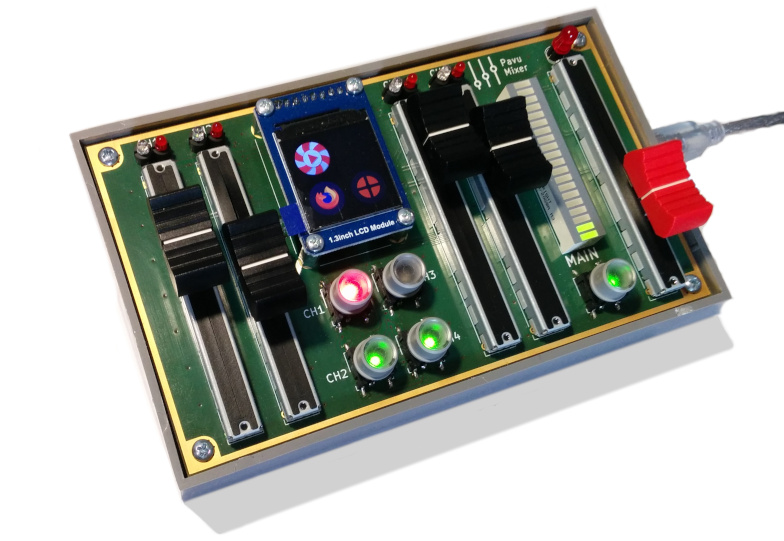

I often open pavucontrol to adjust the volumes of different applications relative to each other.

Sometimes music is too loud, sometimes Jitsi sessions are too silent. However, it is annoying to

switch context ever so often just to open the mixer, change volume, close again. As I am always

looking to challenge myself with some useful projects reaching beyond just writing software, this

felt like a great opportunity: I built myself a small mixing desk to control PulseAudio streams with

hardware faders.

Pavu Mixer is what this resulted in. The project is fully free and open-source, including the hardware. It can all be found on GitHub: https://github.com/rahix/pavu-mixer

In this blog entry, I'm going to detail parts of the journey and the architecture of the project.